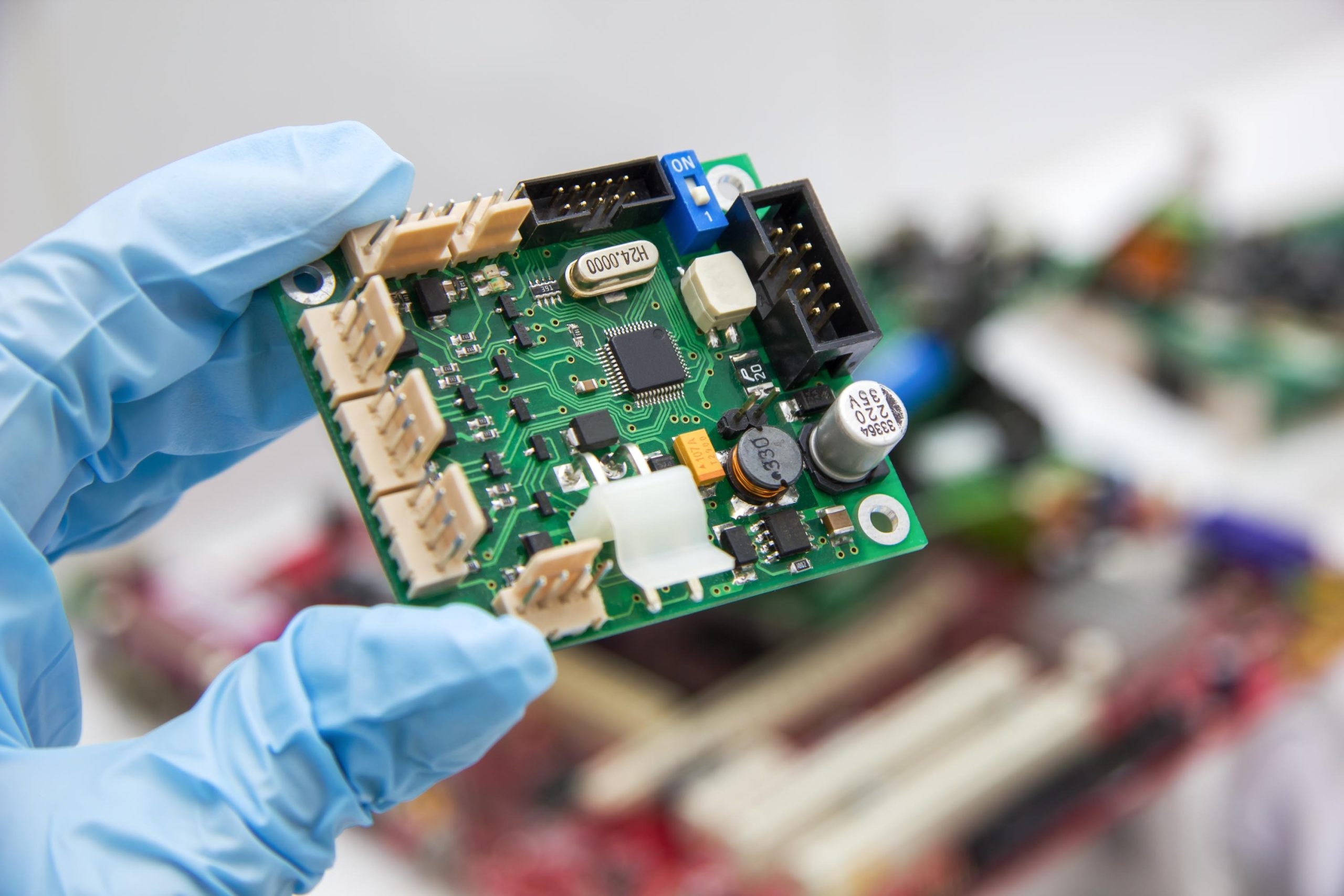

Operating electronic components in the Gulf region comes with immense environmental risks. The circuit boards suffer several factors working against them, i.e., high temperatures, constant humidity, and the presence of particulate contaminants, which ironically, only hasten the process of component failure. Thus, the establishment of strong protection is essential not only for the extension of industrial operations but also for avoiding huge costs linked to the stoppage of production. This is the reason why reliable services for PCB encapsulation UAE are a critical necessity for any operational device.

Assessing Environmental Threats

The unique climate of the UAE puts extreme demands on protective coatings. Continual heat and dramatic thermal cycling cause expansion and contraction that will damage unshielded components, while moisture ingress and corrosive sea air are also constant threats. Effective encapsulation provides an impermeable barrier to these particular regional factors to maintain operational integrity.

Importance of Material Selection

Success mainly depends on the selection of appropriate polymer chemistry. Solutions range from rugged epoxies for mechanical stresses to flexible silicones for extreme temperatures. A premium vendor specializes in tailoring materials to handle the specific demands your device undergoes, ensuring that the selected compound is optimized for resistance and durability across the life of Printed circuit board in the UAE.

Compliance and Certification

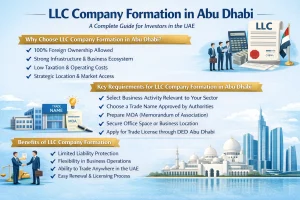

Your selected partner shall demonstrate the highest benchmarks possible within the industry. This would include holding relevant international certifications for quality management and environmental responsibility. Compliance is not just some paperwork or bureaucratic process; it ensures the services and materials meet strenuous, tried-and-tested standards.

Technical Support and Consultation

Top-class service does not stop at the application. Look for partners that provide complete technical support: design-for-manufacture, material mixing, and process optimization. This consultative approach helps you to integrate encapsulation seamlessly into your line, minimizing errors and maximizing long-term efficiency without disrupting workflow.

Choosing a Reliable Partner

Start your selection process with Bodo Moller Chemie, a proven leader whose expertise spans both application and material science. In sourcing solutions for your demanding requirements for PCB Encapsulation UAE, final selection should focus on proven results, technical range, and customized support. For applications requiring guaranteed reliability and top performance under the most unfavorable conditions, you can trust our specialization: an extensive portfolio ranging from technical consulting and custom blending through quality materials to meet your needs.